Pellet machines are a type of equipment that is used to convert various raw materials into small, compact pellets that can be used for a variety of purposes. They are particularly popular in the agricultural and industrial sectors for producing animal feed, wood pellets, and other types of biomass pellets. In this comprehensive guide, we will explore everything you need to know about pellet machines, including their types, construction, operation, and maintenance.

Types of Pellet Machines

There are two main types of pellet machines: flat die pellet machines and ring die pellet machines. Flat die pellet machines are smaller and more affordable, making them suitable for home use. They are commonly used for producing animal feed, wood pellets, and other types of biomass pellets. Ring die pellet machines, on the other hand, are larger and more expensive, making them ideal for commercial and industrial use. They are commonly used for producing large quantities of animal feed and wood pellets. If you are interested in pellet machine manufacturing, visit this website.

Construction of Pellet Machines

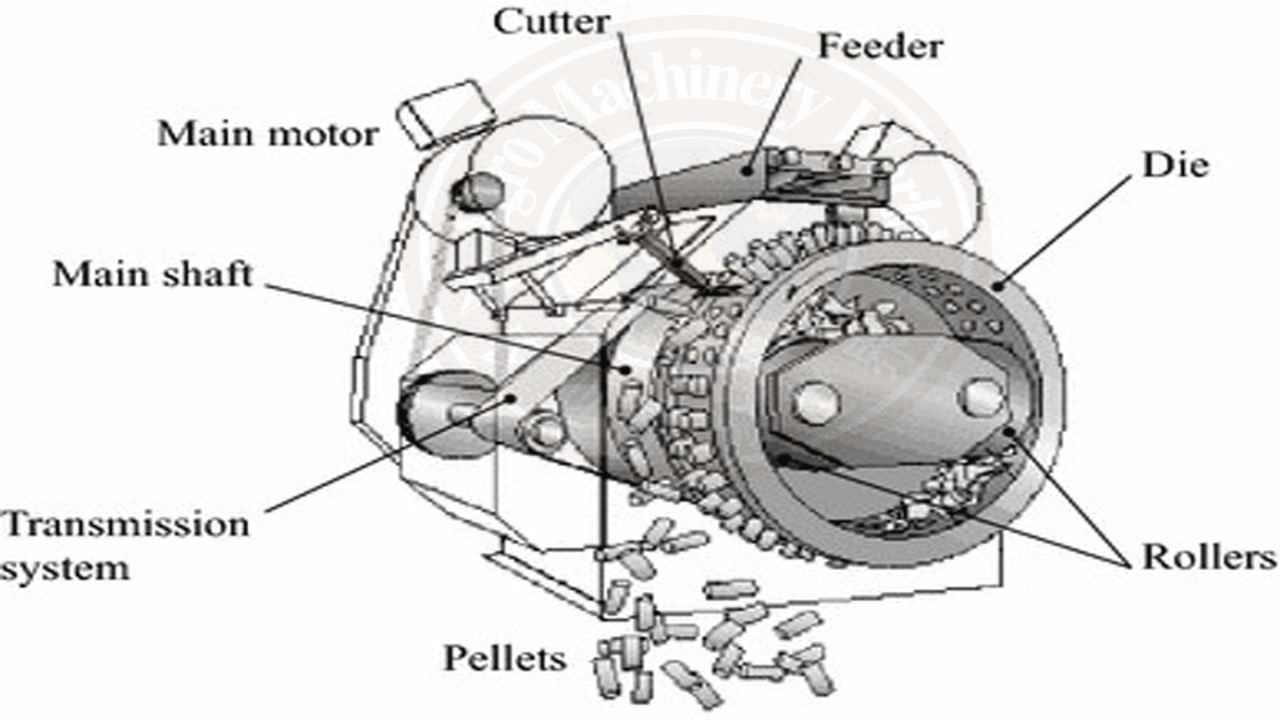

A pellet machine typically consists of several parts, including a feeder, a conditioner, a roller, a die, and a cutter. The feeder is used to transport the raw materials to the conditioner, where they are mixed with steam and other additives. The mixture is then transported to the roller, which compresses the materials under high pressure and temperature. The die shapes the compressed material into pellets, and the cutter cuts the pellets to the desired length.

Operation of Pellet Machines

To operate a pellet machine, you need to first fill the feeder with the raw materials. The materials will then be transported to the conditioner, where they will be mixed with steam and other additives. The mixture will then be transported to the roller, which will compress the materials under high pressure and temperature. The pellets will then be shaped by the die and cut to the desired length by the cutter. The finished pellets can then be collected and stored.

Maintenance of Pellet Machines

To keep your pellet machine running smoothly, you need to perform regular maintenance. This includes cleaning the machine after each use, lubricating the moving parts, and checking the belts and bearings for wear and tear. You should also inspect the die and cutter regularly to ensure they are in good condition.

Benefits of Pellet Machines

Pellet machines offer several benefits, including:

- Reduced Waste: Pellet machines enable the conversion of waste materials into usable products, reducing the amount of waste sent to landfills.

- Cost-effective: Pellets are more cost-effective than traditional fuels like oil and gas, making them an attractive option for heating homes and businesses.

- Renewable: Pellets are made from renewable sources, making them a sustainable and environmentally friendly fuel option.

- Easy to Store: Pellets are small and easy to store, making them ideal for small homes and apartments.

- Versatile: Pellets can be used for a variety of purposes, including animal feed, heating, and even fuel for vehicles.

Conclusion

Pellet machines are an excellent way to convert waste materials into usable products. They are cost-effective, renewable, and easy to store, making them an attractive option for homeowners and businesses alike. With regular maintenance, a pellet machine can last for many years, providing an excellent source of fuel for heating and other applications.