A conveyor system is a mechanical device used to transport materials and products from one point to another within a manufacturing or distribution facility. Conveyors in Australia are widely used in various industries, such as automotive, food and beverage, pharmaceuticals, and logistics, to improve productivity, efficiency, and safety. Here are 8 types of conveyor systems:

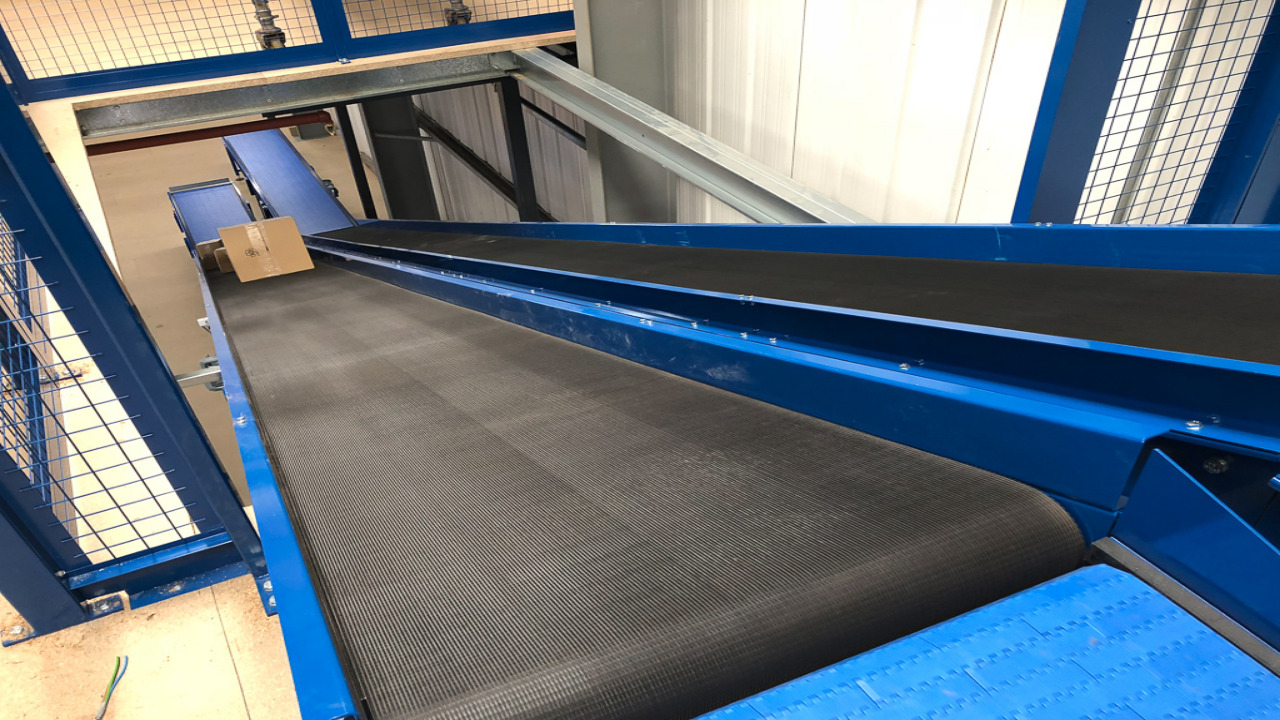

Belt Conveyor

A belt conveyor is a type of mechanical device used for transporting materials and products from one location to another within a manufacturing or distribution facility. The conveyor belt suppliers typically sell belt conveyors made of rubber, fabric, or metal.

Belt conveyor systems can be horizontal, inclined, or declined and are widely used in various industries such as food and beverage, pharmaceuticals, logistics, mining, and agriculture. Belt conveyors are highly versatile and can handle a wide range of materials, including bulk materials such as grains, sand, and coal, as well as packaged products like boxes, cartons, and bags.

Roller Conveyor

A roller conveyor is a type of mechanical device used to transport materials and products from one point to another within a manufacturing or distribution facility. Roller conveyors consist of a series of rollers that are mounted on a frame and rotate around their own axes to move materials along a fixed path.

Roller conveyors are commonly used for transporting heavy or bulky items, such as pallets, drums, and large containers. They can be powered or non-powered and can be designed to handle different types of loads and materials. Gravity roller conveyors, for example, use the force of gravity to move materials along the rollers, while powered roller conveyors use a motor to drive the rollers.

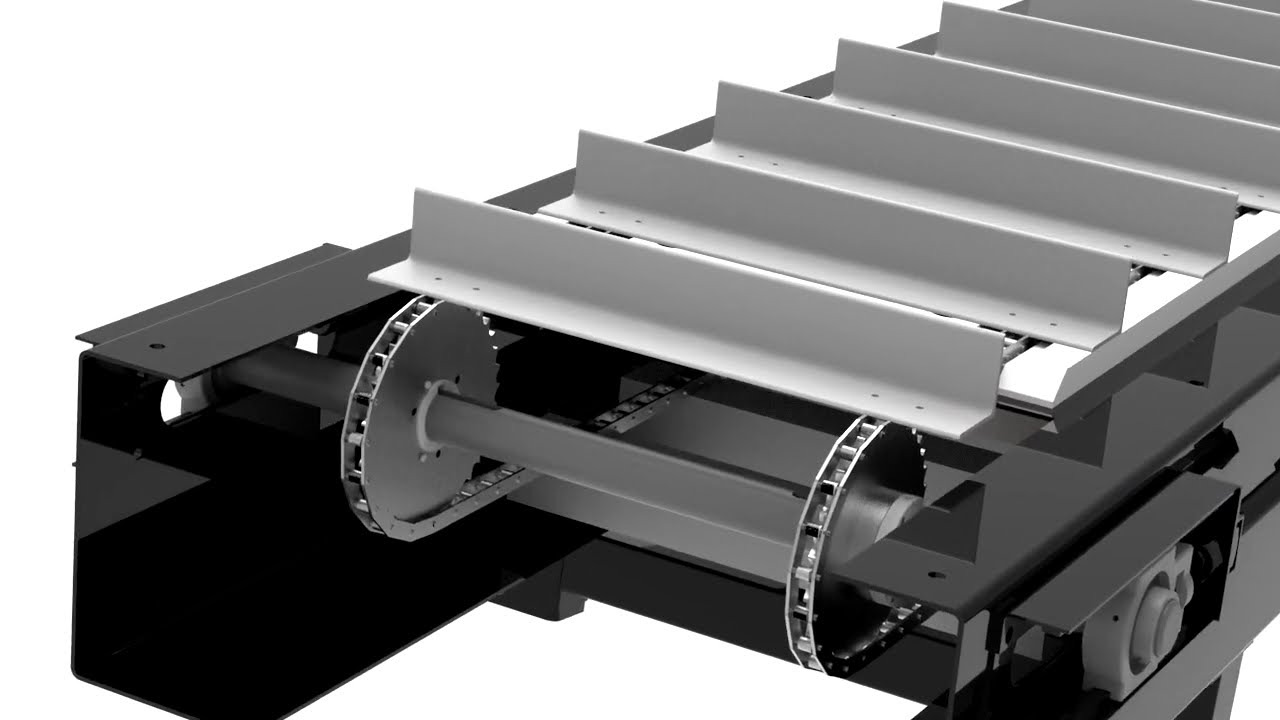

Chain Conveyor

A chain conveyor is a type of mechanical device used to transport materials and products from one point to another within a manufacturing or distribution facility. Chain conveyors consist of a chain that is mounted on a series of rollers or sprockets and moves materials along a fixed path.

Chain conveyors are commonly used for heavy-duty applications and can handle a wide range of materials, including bulky and abrasive materials, such as steel, automotive parts, and pallets. They are reliable and can withstand harsh environments and heavy loads.

Screw Conveyor

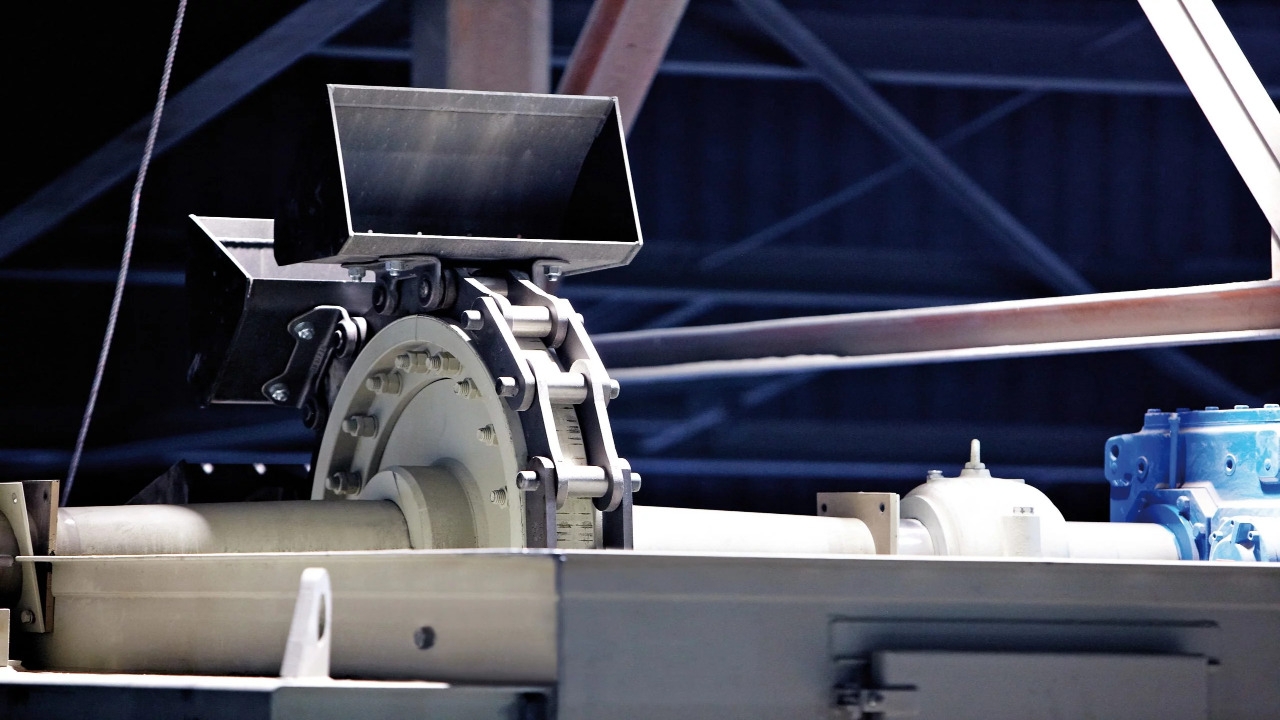

A screw conveyor is a mechanical device used to move materials from one point to another in a vertical, inclined or horizontal direction. It consists of a screw or helical blade, which is rotated within a cylindrical tube or trough, causing the material to move along the length of the tube.

Screw conveyors are commonly used in a variety of industries, including agriculture, mining, food processing, and construction. They can handle a wide range of materials, including powders, grains, and other bulk solids, as well as liquids and slurries.

Bucket Conveyor

A bucket conveyor, also known as a bucket elevator, is a type of mechanical conveyor system used to move materials vertically. It typically consists of a series of buckets attached to a belt or chain that rotates around two or more pulleys or sprockets, allowing the buckets to move up and down between different levels.

Bucket conveyors are commonly used to transport bulk materials, such as grains, fertilizers, aggregates, and powders, from one level to another in a production or processing facility. They are also used in the mining and construction industries to transport heavy materials such as ores and construction materials.

Vibrating Conveyor

A vibrating conveyor is a mechanical device used to transport materials using a vibrating motion. It typically consists of a trough or tube that is supported by springs or other vibration-absorbing devices and is vibrated by an electric motor or pneumatic piston.

The vibrating motion of the conveyor can be horizontal, vertical, or inclined, depending on the application and material being transported. This type of conveyor is commonly used in food processing, chemical processing, mining, and packaging industries.

Vibrating conveyors are particularly useful for transporting fragile or delicate materials that can be damaged by traditional conveyor systems. They can also be used to transport hot or corrosive materials that may damage other types of conveyors.

Overhead Conveyor

An overhead conveyor is a type of conveyor system that is mounted to the ceiling or overhead structure of a building, allowing materials to be transported along a fixed path above the ground.

Overhead conveyors are commonly used in manufacturing and distribution facilities to move products or materials from one location to another, such as from a production line to a storage area or shipping dock. They are particularly useful in applications where floor space is limited, as they can transport materials without taking up valuable floor space.

Magnetic Conveyor

A magnetic conveyor is a type of conveyor system that uses magnets to transport ferrous materials, such as iron, steel, and other magnetic materials. The magnetic conveyor consists of a conveyor belt or a series of rollers with powerful magnets mounted beneath them.

As the conveyor moves, the magnets attract the ferrous materials on the conveyor, holding them securely in place and moving them along the conveyor path. This makes magnetic conveyors particularly useful in applications where traditional conveyors cannot be used due to the material being transported, such as in the recycling or scrap metal industries.